| 工作电压 | 380V |

|---|---|

| 用途 | 工件加热 |

| 品牌 | 欧能 |

| 型号 | EUDC |

| 加工定制 | 是 |

| 加热器类型 | 管式换热器 |

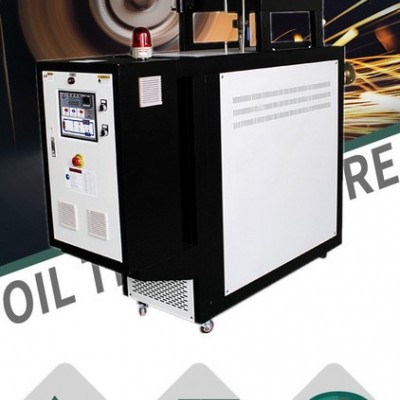

压铸专用模温机

江苏南京欧能机械有限公司专业生产模具温度控制机, 350度高温油温机,180度高温水温机,镁合金压铸模温机(铝、锌合金压铸模温机)。精密压铸件成型的时候,根据产品的需求会用压铸模温机来恒定温度。

由于合金压铸模具存在模具温度高、模具管路口径小、需要扬程大的高温油泵的特点,欧能机械针对压铸行业开发出来的一款高性能的压铸模温机:使用工作油温最高达350℃,采用当今世界最先进的流程设计,控温精度高,导热速度快,高效节能。并可配置自动吸出回油、全负压运转、RS485通讯等功能,完全可与当今代表最高水准的欧洲进口模温机相媲美。跟国内同行业相比性能更高,价格更优惠,是众多压铸厂家的首选模温机。

压铸模温机特点(Features)

1、管路防爆裝置(選購)

Explosion-proof equipment (optional)

2、回油溫度顯示表.

Thermometer for return oil

3、開機自動排氣功能

Automatic air-exhausting function after startup

4、油泵反抽回油功能

Return oil back suction of oil pump

5、加熱功率切換功能.

Switchover of heating power

6、负压系统运转(选购)

Negative-pressure system(optional)

7、即時冷卻關機功能(选购)

Instant cooling return oil shut-down function(optional)

8、隔離式電器控制箱. 延長電器使用年限.

Isolated electric box for longer services lives of electric appliances

9、RS485通訊功能,實現自動化管理.(选购)

RS485 communication function for automated management (optional)

10、熱油BY-PASS泄壓回路

BY-PASS pressure release loop for hot oil

11、多點溫度控制機組可訂作

Customizable multi-point temperature control unit

12、油泵馬力和加熱功率可訂作

Customizable horsepower and heating power of oil pump

13、全系列采用德国SPECK油泵(磁力泵)

SPECK oil pumps (magnetic pumps never suffering from oil leakage)imported from Germany for all series products

14、全系列采用欧美高温管路元件

American and European high-temperature pipeline components for all series products

15、溫度控制範圍: 油溫+15℃→320℃

Range of temperature control: +15℃→320℃ for incoming water

16、電器採用OMRON. FUJI. TE. LG. MOELLER. ABB.等

Brands OMRON, FUJI, TE and LG for electric appliances

17、304不銹鋼一體管路,減少管阻及鏽垢

304 stainless steel integrated pipelines for less pipe resistance and rust

18、控制方式: 採用進口微電腦或(選購)PLC控制

Control mode: imported microcomputer or PLC (optional)

19、安全保護完善,故障顯示, 維修.保養無需專業人員

Perfect safety protection, fault display, easy repair and maintenance even without professionals

压铸模温机规格 (Specifications)

项目 | ITEM | 單位UNNIT | EUDC-18 | EUDC-36 | EUDC-48 | EUDM-18 | EUDM-36 | EUDM-48 |

溫控範圍 | Temp control range | ℃ | 進油溫 Inlet water temperature+15℃~320℃ | |||||

溫控精度 | Temp control accuracy | ℃ | PID±1℃ | |||||

電源 | Power supply | AC3∮380V 50HZ 3P+E(5M) | ||||||

傳熱媒體 | Heat transferring medium | 导热油 indirect cooling | ||||||

冷卻方式 | Cooling method | 直接冷卻 Indirect cooling | ||||||

膨胀油箱大小 | Expansion tank capacity | L | 25 | 25 | 30 | 30 | 30 | 30 |

加熱能力 | Heating capacity | kw | 18 | 36 | 48 | 18+18 | 36+36 | 48+48 |

泵浦功率 | Horsepower of pump | Kw | 0.55 | 1.1 | 2.8 | 0.55+0.55 | 1.1+1.1 | 2.8+2.8 |

泵浦工作流量 | Working flow of pump | L/min | 20 | 40 | 60 | 20+20 | 40+40 | 60+60 |

泵浦工作壓力 | Working pressure of pump | Kg/cm2 | 2.0 | 2.0 | 2.8 | 2.0+2.0 | 2.0+2.0 | 2.8+2.8 |

最大電力消耗 | Maximum power consumption | kw | 19 | 26 | 52 | 38 | 52 | 104 |

特殊功能 | Special function | 泵浦反转回油功能Oil retum by pump reversal | ||||||

報警功能 | Alarm function | 缺相/缺水/超溫/超載/反轉 Open phase/water depletion/excess temperature/overloading/reverse turn | ||||||

冷卻水配管 | Cooling water pipe | inch | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 |

循环油配管 | Circulating water pipe | inch | 3/4 | 3/4 | 1 | 3/4×2 | 3/4×2 | 1×2 |

整機參考尺寸 | Size(L*W*H) | mm | 整机参考尺寸 | |||||

以上規格如有變更,恕不另行通知,特殊規格可另行設計改造

The specifications above are subject to changes without notice.Some special specifications may be customized.

客服热线:

客服热线: